Kunshan Des‑Valve Precision Machinery Co., Ltd (DSV) is a specialist with over 15 years’ experience in pneumatic transmission and mixing equipment, operating under ISO 9001:2015 standards and backed by high‑tech enterprise certifications including explosion‑proof certification CJEx19.0349X and CJEx21.0370X.

They manufacture and supply a broad range of pneumatic products, including Air Mixing Tanks, Air Diaphragm Pumps, and Drum Pumps, serving industries such as chemicals, pharmaceuticals, coatings, food & beverage, cosmetics, paper, and more.

Air Mixing Tank

DSV’s Air Mixing Tanks are designed for efficient, uniform mixing of liquid/liquid or liquid/solid materials using pneumatic agitators. Available variants include stainless steel (SUS304/SUS316L), plastic (PP/PE), jacketed tanks, and drum‑mounted tanks with agitator modules.

Typical features and benefits:

- Versatility: Suitable for paint, chemicals, cosmetics, food ingredients, pharmaceuticals, adhesives, inks, dyes, rubber pastes, and more.

- Customized configurations: Options like mirror‑polished stainless cabinets, jacketed heating/cooling, pressure or vacuum capability, and tailored volume/shape to suit process needs.

- Efficient mixing: Air‑driven agitators deliver stepless speed control, improved blending, and homogeneity, reducing mixing time and manual labor.

- Installation & maintenance guidance: Detailed instructions ensure proper foundation anchoring, correct sealing, adjustment and commissioning process. Ongoing guidance covers cleaning, seal checks, transmission lubrication, calibration, and corrosion prevention.

Ideal for: scaling up from R&D to large batch production in industries requiring stringent hygiene and mixing quality.

Air Diaphragm Pump

The Air Diaphragm Pump series from DSV includes 1″, 2″, and stainless steel designs, built from materials like engineering plastics, aluminum alloy, cast iron, and various diaphragm rubbers (nitrile, neoprene, PTFE, fluorine rubber) to ensure compatibility with diverse fluids.

How it works and core advantages:

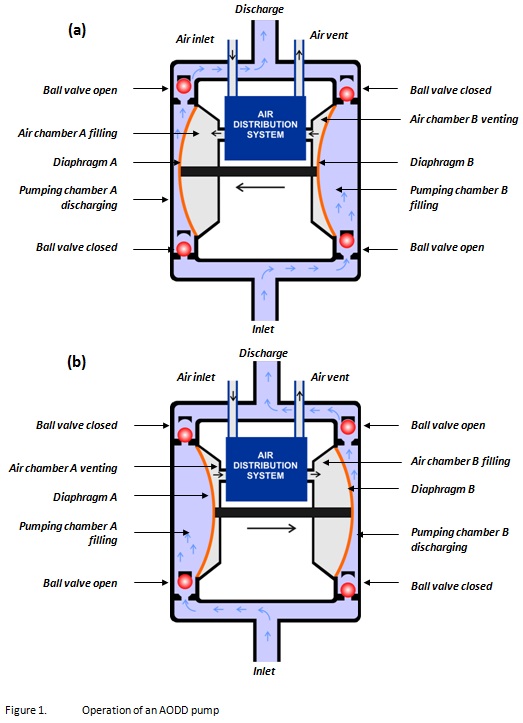

- Pneumatically powered: uses compressed air to flex diaphragms, creating suction and discharge cycles. No electric sparks and ideal for hazardous environments.

- Self‑regulating flow: adjusting air pressure or valves modulates flow rate, with automatic shutdown if the discharge valve is closed—no overheating or energy wastage.

- Self‑priming & dry‑run capable: can suction fluids from up to 7 m (head up to 50 m), even dry, without damage. Handles abrasive slurries, corrosive chemicals, viscous and volatile fluids.

- Robust & safe: no rotating mechanical seals, minimal wear parts, leak‑free operation, and inherently explosion‑proof design.

Typical applications: chemical processing, wastewater treatment, food and beverage, pharmaceutical batching, slurry handling in mining and construction, oil & gas transfer, adhesives, paints, sewage sludge, and corroded or hazardous fluids.

Maintenance tips:

- Replace worn O‑rings to prevent leaks.

- Check inlet/outlet lines and valves for blockages.

- Ensure mufflers aren’t icing in humid, cold conditions.

- Use proper grounding and anti‑static hoses to prevent static buildup.

Drum Pump

DSV’s Drum Pumps (also known as air-operated drum pump or barrel pumps) are engineered to efficiently transfer liquids from large containers or barrels using compressed air. These are available in stainless steel or customized configurations.

Key design & operation features:

- A suction tube inserted into the drum connects to a motor and discharge hose. Compressed air through the motor creates a vacuum pulling fluid upward and pushing it out via the discharge line.

- Simple, portable, and versatile: compatible with many drum sizes and liquid types (chemicals, fuels, oils, syrups, adhesives).

- Comes standard with pressure regulator, relief valve, pressure gauge, locking nut, O‑ring/gasket sets and connect threads to match drum openings.

- Designed for safety: grounded operation, minimal static buildup, suitable for flammable or corrosive media.

Benefits:

- Rapid transfer and easier handling of viscous, hazardous, or abrasive fluids from drums or totes.

- Reduces manual pouring, enhances workplace safety and efficiency.

Typical uses: petroleum transfer, chemical drums, food & flavor barrels, industrial lubricant transfer, solvent dispensing in labs or production lines.

Why Choose DSV?

DSV combines exceptional product range with robust manufacturing and support:

- Established expertise and quality control: operating under ISO 9001:2015, explosion‑proof certification, and recognized as a high‑tech enterprise.

- OEM/ODM flexibility: customize tanks, pumps, diaphragms, materials and capacities to match customer’s specific process requirements.

- End‑to‑end services: free pre‑sales consultation, tailored design schemes, rapid response within 12 hours, warranty coverage of one year, and global logistics support.

Use‑Case Scenarios

1. A chemical plant mixing reactive agents uses a stainless steel Air Mixing Tank with agitator, ensuring consistent fluid blend under controlled temperature and pressure.

2. A mining site handling abrasive slurries uses a 2‑inch Air Diaphragm Pump to transfer slurry safely without clogging or wear.

3. A beverage manufacturer moving solvents or flavors from drums uses a stainless steel Drum Pump for hygienic and efficient fluid transfer.

Summary

Air Mixing Tank: reliable, scalable mixing solutions for diverse industries.

Air Diaphragm Pump: secure, self‑priming, abrasion‑resistant pump powered by compressed air.

Drum Pump: air‑operated systems for safe, efficient transfer of liquids from drums or containers.

All are crafted with DSV’s pneumatic expertise, supporting explosion‑proof safety, customization, and strong after‑sales service. These solutions empower manufacturers to achieve consistent quality, operational safety, and process efficiency across sectors.

Comments on “Top Applications of Drum Pumps, Air Diaphragm Pumps, and Air Mixing Tanks”